Sandblast Signs, Old World

Sandblasted Signs are common in some places. In downtown historic areas like Carlsbad, in vineyards and in historic areas. As maintenance and renovation in these areas is needed, new sandblasted signs are also needed. How do these signs get made?

It starts with the “wood”

It starts with the “wood”: There are few options, but these are Redwood, Cedar and HDU. HDU is High Density Urethane. Lighter than wood, it never rots and termites have no interest in it. HDU is fragile, has no wood grain and lacks the strength of wood. Cedar has some natural insect resistance, and is strong, but it is stringy and does not sand blast nearly as well as Redwood. Redwood is our preferred material. It is dense, strong, has wood character.

The Bounce pad

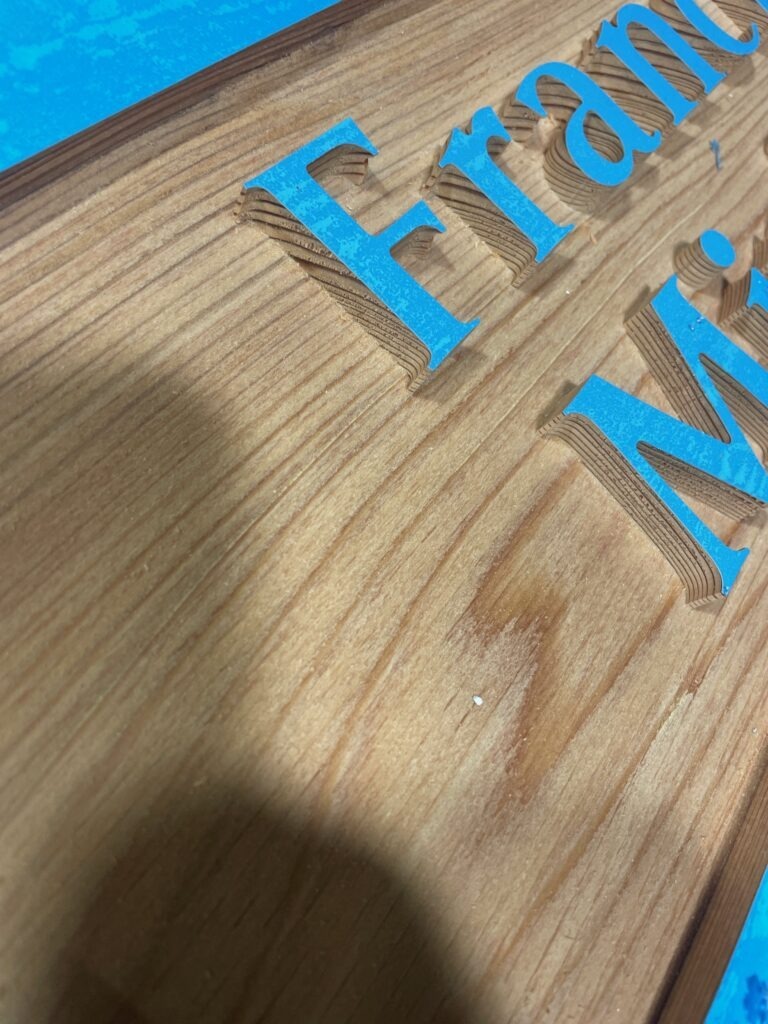

The Bounce pad: Once the wood is cut, we have a blank. Then we apply a special pad, a sandblast mask. This should protect those “high’ areas from the sand. It does and it does not. The wood blasted away is anything exposed. All wood has a grain and inside that grain are soft and hard areas. Sand blasting will undercut your letter and cause problems, the deeper the cut, the worse it gets, but shallow cuts do not show dimensionality. We have a way to cut the letters deeply before sandblasting to get the best of both.

Finishing touches: All sand blasted signs are painted. A lot of this work is done by hand. Normally a quality exterior oil-based paints are used. There are just hours of hand work.

The results are not “perfect” because the wood has a charter all its own, the grain of the wood and the natural variations come through. At Signs for San Diego, we like Sand Blasted Signs. Ours are deeper showing more relief, the paint is better, and the results are better as well. Interested? Give us a call.