Monument Signs What is a Pan and Why Do I Need One?

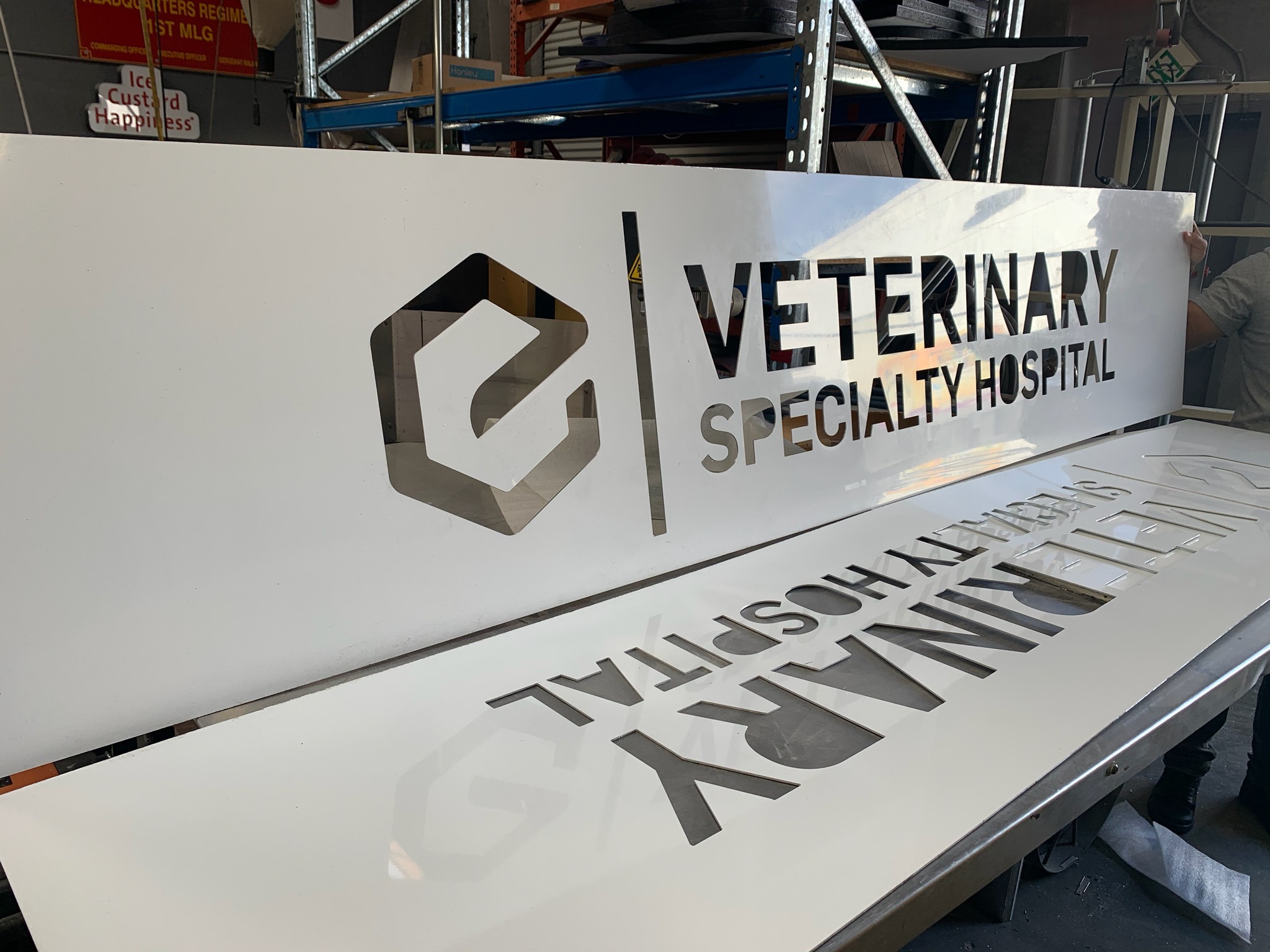

Mall Monuments are built to highlight the tenants. The tenant panels are for each business or retail shop. In many retail monument signs the specific kind on panel is a pan face. These come is a range of types: The most common Pan face is an Aluminum Pan with routed out outlines of the company letters and logo and a sheet of Acrylic underlaying the holes. This is an underlay pan face. The next type is the same, but the acrylic is thicker and “pushed through” the routed-out outlines. This is a push through face. One example is Veterinary Specialty Hospital an example of San Marcos CA Signs.

At Signs for San Diego, we have the massive metal working equipment to bend and shape these faces quickly and at minimal cost and will last a long time..

Kohl’s Laguna Niguel CA is a great example of one of many Laguna Niguel Ca Signs. We work with the mother of all metal working equipment: a 3,000 pound metal brake. This machine shapes a flange on the panel and makes the “pan”.

We can build it for you

Often customers bring us monument pan faces from the former tenant. We use these as patterns to build new pans or we reuse the old pans. A lot depends on if the pans are reusable. We often cut out the old face and put a new face right over the top. Sometimes we strip off many faces if the pan has been through many updates.

We Restore Pan Faces

Often years of sun take its toll on a pan face. We can strip and restore it to its original condition when needed. We have the paint facilities to renew an old face and get many more years of use out of it.

Cut Outs

A Pan itself is just a vehicle for the actual sign. It is the substrate. The faces are cut outs. These are normally Aluminum. The outlines of the letters and logos are cut with a router. The computer-controlled router cuts precisely. We can cut the pan, but it is more common to cut a flat piece of aluminum and mount it to the pan.

How refacing a Pan Sign Works

Here is an example of a pan face sign. It came in from another sign company. It was pulled on a retail shopping mall monument and was for the new tenant. We recently received a pair of pan faced monument tenant signs. They were blank, another sign shop had glued a blank panel on top of the old sign. They looked OK and we thought we could route the new tenants company name and logo without too much effort. Our plan was to cut the blanks that were there in the shapes we needed and that would be successful We do this with a CNC router, in this case a Multicam, the most popular router for signs. We started and it was pretty quickly obvious our original plan was not going to work. These blank faces were thick, really thick. So, we continues to cut, making multiple passes until we saw what was really there.

Cutting the Face

As we cut down into the faces, pass after pass, we saw this pan face had a number of other signs under it. At least 5 other signs had been covered up and were layered over and over. We were able to cut through, but the thickness was close to an inch of different Aluminum, plastic, and voids. It was a very thick layered core. Worse, with the lack of uniformity, the core having all different materials and different thickness, there was just no way to reuse this another time. It was too far gone. We could not repair this pan face. It was too thick, used too many times and just not workable.

Rebuilding

Often rebuilding an old sign is more expensive than just building a new sign. The only part that could be saved was the frame. We took the frame and stripped the layers off; this was involved and took some time. The frame, free of the faces, was stripped and prepared for a new face. We have sheet Aluminum in stock and selected a sheet of 063 Aluminum for our new face. Routing the letter and logo profile in the new sheet we also cut the parameter out. Then we joined the face to the frame with a 2-part epoxy. The epoxy is a cold joining method and does not distort the face like a welding operation might. It also is stronger than a welded face. These were prepared by roughing up the surface for superior paint adhesion, a primer followed by a finished coat were applied. We use a commercial paint system designed for signs called the Matthews Paint System. This gave us a very good pan; face and we were ready for acrylic.

Finished Pan Face

The Acrylic is prepared by shaping it with the CNC router, cleaning it, and applying vinyl. The vinyl is a translucent red and blue. After attaching the acrylic to the pan, we have the finished sign.

Types of Faces

Once the holes are through the metal, the sign maker uses acrylic and vinyl to make your sign’s color, image, and shape. There are 2 types. Underlay is where the acrylic lays under the pan. These are the most common. A push through is where a thicker acrylic is routed out to go through the aluminum and sit above it. This allows light to come out he sides and create a halo effect. There is a third type where the acrylic is cut to push through up to the surface and is on the same plane as the aluminum face. These are not that common because they have all the costs and work of the push through with none of the advantages. Pan face signs go for a premium price compared to just a flat acrylic panel. Pan Face Signs look better and are found on High-end retail shopping malls.

Need a sign company to make a pan face Monument Sign for your business? At Signs for San Diego, we can maintain your sign, change out and face, or build the whole thing. Let us help you create the perfect sign – give us a call!