Local vs remote manufacturing

Project Managers and Estimators : Are you using all your options?

Every Project Manager and Estimator has “issues” with site locations, people, and time. Each site you service has hundreds of details that can become problems. Multiply this with the number of sites and there are thousands of little details to coordinate and manage. There are really 2 types of costs 1) the dollar amount and 2) the amount of time needed to get the job completed.

Where to Manufacture

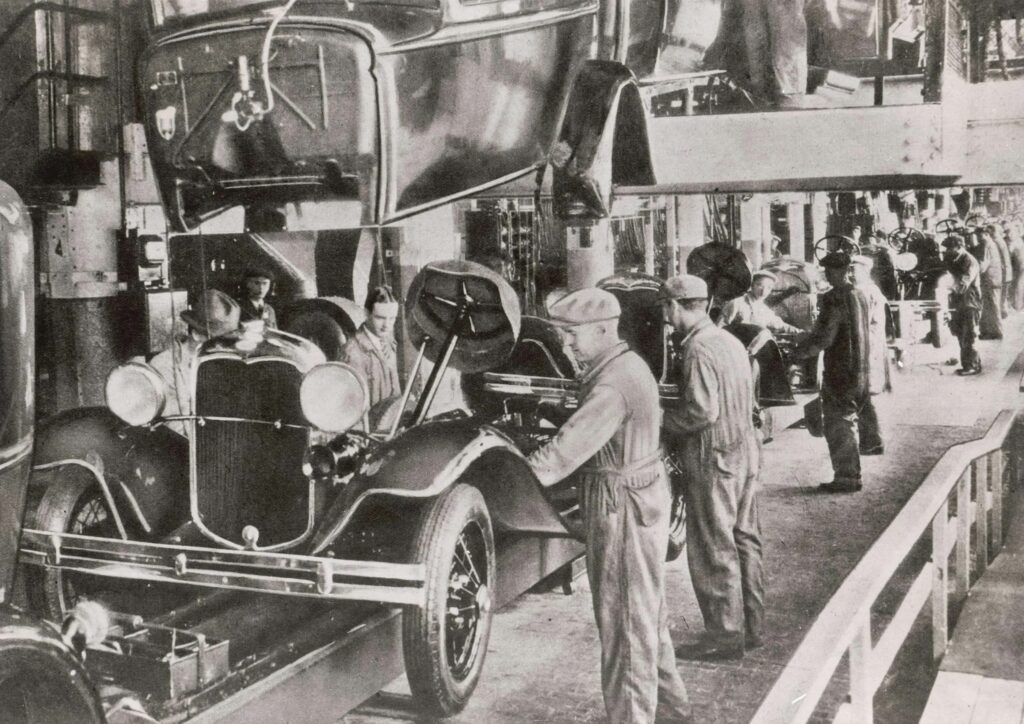

It is easy to manufacture all signs at one site. There are volume discounts and when a shop “team” builds the same basic sign over and over – they get good at it. Unmatched uniformity and control can be achieved. The best example of this is in vacuum formed faces. While the mold is expensive, copies are cheap. The savings can be dramatic. The problem with “signs” is that all the location requirements are potentially different. San Antonio real-estate is not like Bangor Maine, even worse the local sign ordinance is written under the direction of the electee city council. Every little city has differences in their requirements. Signs are custom built to t the location, the business, and the local requirements. Add in the shipping and centralized manufacturing loses its advantages.

The actual situation varies, but the reason the sign industry does not look like the automotive industry or the computer industry is the local requirements prevent uniformity. It is more like the housing or construction industry. So how can an Estimator quickly get the best deal? It is this cost formula:

Cost of the Sign built remotely + Shipping Verses the cost of local manufacture

Shipping, the cost of delivering a small sign can equal the cost of the sign itself. Larger signs that cannot be sent “common carrier” can be prohibitive. With fuel prices up, the costs are also up, way up

The second problems is how much time does it take to get is “right”

Things happen in shipping. Does UPS love you? Think again – signs getting dropped, forked, and generally abused. It is not just the shipper cost; it is the packaging. Will a basic create work, or are you spending $100 or more on wood, foam, tape, and labels? If manufacturing near the target install site is marginal higher priced, it can still cost less.

Time

Time, it takes time to ship. Everything else takes time as well, adding 3-5 days to the project to wait for a truck slows down everything, and if multiple shipments are needed, the time can be a major issue

Warranty issues – Not everything goes perfectly all the time and when there is a need to service an installed sign, do you need to go back to a production team that really is too busy to replace a single face or letter? Is the paperwork alone more costly than the replacement part? There really are on upsides to repairs during install or for the warranty period. It is really about choosing the least bad alternativeThe truth is a combination of manufacturing centrally and custom work locally is the most cost effective.

The advantage of local manufacturing.

At Signs for San Diego, we have the same Accubend as your production team. We have the paint booth and use the same Matthews paint system as your factory. Our staff often has national sign company experience and usually older and more experienced than most. We have MiG Aluminum expertise and of course the Multicam CNC routing abilities. Our materials are the same. There are a few differences:

No shipping – without the shipping cost and the shipping time installs happen quicker

No delay is replacements. When there are: damage, missing parts, last minute changes, we use the same materials (often the same exact sheet, roll of vinyl, or LED batch) to make replacements. They are a spot-on match and can happen in hours, not days or weeks. Often the problems are entirely local, solved between an installer and shop guy, never even noticed by the customer and out of your hair – you management is less, your install time is less, your costs are less, it is a win win win (installer, end user and you)

Warranty – Unfortunately clocks get reset, switches get accidentally turned off, Power supplies fail, wiring connections fail, weather (like hail) happens and a warranty claim results. When that claim comes to you, then to the local installer, then back to you then to the manufacturer, then ship the part then manage the service you are involved in a multistep process, it takes time. But what if the installer is the manufacturer? All those steps disappear, the repair happens faster and the customer is happier. Your involvement is much less. It is just more ecient

Out of warranty repairs. Service and install are different businesses and require different approaches. There is money in both, but service has less money per transaction and every service need is local and unique. It is really hard to manage service remotely. But if the sign is made in one location and the service need hundreds or thousands of miles away, it can become a problem. However, if the manufacturer is the service provider you have a huge advantage. The same parts are local, the same people who installed the sign know all about it and can service it better and the same people who built the sign can make the parts. If these issues can be ooaded to the local installers, the situation becomes easier and more manageable.

By using all your options, the total cost can be minimized or optimized. Every issue with site locations, people, and time is solved in the end. Were these solved in the quickest and most cost-effective way? Probably not. Getting closer to that optimal mix takes time to learn. Having options like local manufacturing open up the opportunity to be more ecient. There are really 2 types of costs 1) the Price of the sign plus shipping and adjustments and 2) the amount of time needed to get the job completed. Can Signs for San Diego save you money time and trouble? With unique locations, sizes, and high shipping cost – very likely we can help you save time and money. Give us a call and let’s nd out!!